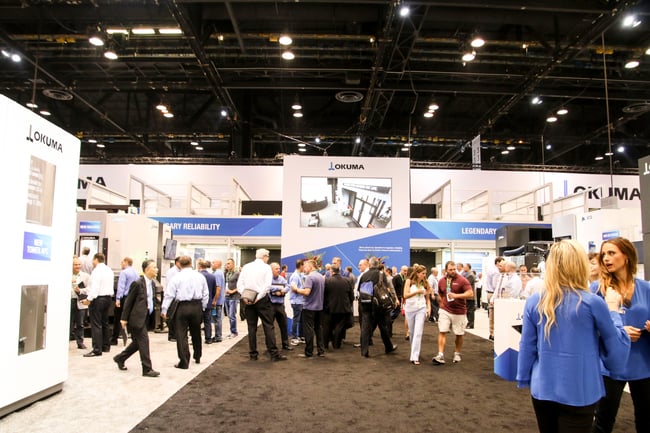

Join Gosiger at the Precision Machining Technology Show (PMTS) 2025, taking place from April 1–3, 2025, at the Huntington Convention Center in Cleveland, Ohio. As a leading provider of advanced manufacturing solutions, Gosiger is excited to showcase cutting-edge technologies designed to enhance your machining operations.

Okuma CNC machines are respected the world over for quality, reliability and industry-leading manufacturing technology. Among the many reasons is the user-friendly OSP open source control system. The award-winning

Okuma CNC machines are respected the world over for quality, reliability and industry-leading manufacturing technology. Among the many reasons is the user-friendly OSP open source control system. The award-winning

You can download these and other free APPs from industry-leading tooling company,

You can download these and other free APPs from industry-leading tooling company,  Ideal for complex, multi-sided machining, the new

Ideal for complex, multi-sided machining, the new  Wishing to gain insights into the key issues facing CNC machine shops, Gosiger, Inc. recently sponsored a roundtable discussion among a dozen shop owners and managers in southeast Ohio. The event was held at the Aileron center for business development, north of Gosiger’s Dayton headquarters. Participants also heard a presentation by

Wishing to gain insights into the key issues facing CNC machine shops, Gosiger, Inc. recently sponsored a roundtable discussion among a dozen shop owners and managers in southeast Ohio. The event was held at the Aileron center for business development, north of Gosiger’s Dayton headquarters. Participants also heard a presentation by

If you’ve considered the advantages of a

If you’ve considered the advantages of a  Women make up 47% of the US workforce, but only 24% work in manufacturing. This amounts to a

Women make up 47% of the US workforce, but only 24% work in manufacturing. This amounts to a

.jpg) In another example of Gosiger Automation designed robot-based factory automation,

In another example of Gosiger Automation designed robot-based factory automation, .jpg) Manufacturers need no longer choose between CAM actuated automatic and CNC multi-spindle machines. U.S. machine tool distributor and factory automation specialist, Gosiger, Inc. has partnered with industry-leading Japanese multi-spindle machine builder Shimada to create the new, ISM B27 hybrid CNC multi-spindle bar machine.

Manufacturers need no longer choose between CAM actuated automatic and CNC multi-spindle machines. U.S. machine tool distributor and factory automation specialist, Gosiger, Inc. has partnered with industry-leading Japanese multi-spindle machine builder Shimada to create the new, ISM B27 hybrid CNC multi-spindle bar machine..jpg) As a CNC factory owner or manager you know the importance of making your manufacturing processes as efficient as possible. To a great extent this means investing in

As a CNC factory owner or manager you know the importance of making your manufacturing processes as efficient as possible. To a great extent this means investing in  Picture a factory at night, pumping out perfect parts with no one around. No labor costs, lower energy expenses and a customer order ready for shipping the next morning. Is it a dream or reality? Well, with today’s advanced manufacturing and communications technologies, lights out manufacturing can be a reality for everything from the smallest CNC machine shop to the largest factories.

Picture a factory at night, pumping out perfect parts with no one around. No labor costs, lower energy expenses and a customer order ready for shipping the next morning. Is it a dream or reality? Well, with today’s advanced manufacturing and communications technologies, lights out manufacturing can be a reality for everything from the smallest CNC machine shop to the largest factories. Gosiger software specialists developed this A2P (Application-to-person) messaging system to enable Okuma machine owners to receive text alerts from their CNC machine tools directly to their smart phones. Using SMS technology and Internet access, GO-TextAlert allows multiple phone numbers to receive trouble alarms, status codes and customized data.

Gosiger software specialists developed this A2P (Application-to-person) messaging system to enable Okuma machine owners to receive text alerts from their CNC machine tools directly to their smart phones. Using SMS technology and Internet access, GO-TextAlert allows multiple phone numbers to receive trouble alarms, status codes and customized data. Despite all of your efforts to increase productivity through advanced CNC machine technologies, factory automation and smarter machining techniques, unnecessary machine downtime can eliminate everything you’ve gained. That’s why a planned preventative maintenance program (PPM) is so important. And it really isn’t all that complicated. In fact the basics of PPM can be summed up in these 5 actions:

Despite all of your efforts to increase productivity through advanced CNC machine technologies, factory automation and smarter machining techniques, unnecessary machine downtime can eliminate everything you’ve gained. That’s why a planned preventative maintenance program (PPM) is so important. And it really isn’t all that complicated. In fact the basics of PPM can be summed up in these 5 actions: Studies show that human beings are not particularly good and multitasking, despite our belief that we can successfully do more than one thing at a time. That’s why talking and texting while driving leads to so many bad outcomes.

Studies show that human beings are not particularly good and multitasking, despite our belief that we can successfully do more than one thing at a time. That’s why talking and texting while driving leads to so many bad outcomes..jpg) Trochoidal milling can help resolve many challenging CNC machining operations such as:

Trochoidal milling can help resolve many challenging CNC machining operations such as:

Workpieces often leave a machine tool covered with metal dust, dirt, chip remnants and machine oils. Whether these are parts for your own products or components to be shipped to a customer, they typically need thorough cleaning. Doing so manually means increased labor costs, machine downtime and the cost of cleaning agents, as well as their proper disposal, whether solvent- or aqueous-based.

Workpieces often leave a machine tool covered with metal dust, dirt, chip remnants and machine oils. Whether these are parts for your own products or components to be shipped to a customer, they typically need thorough cleaning. Doing so manually means increased labor costs, machine downtime and the cost of cleaning agents, as well as their proper disposal, whether solvent- or aqueous-based. Shortening machining cycle time, reducing labor costs and extending tool life can all play a major role in improving productivity and, thereby, your bottom line. While using the most advanced machine tools is certainly a key component in achieving greater productivity, it’s not the entire answer. It’s equally important to optimize all aspects of a manufacturing operation from raw materials through delivery to the customer.

Shortening machining cycle time, reducing labor costs and extending tool life can all play a major role in improving productivity and, thereby, your bottom line. While using the most advanced machine tools is certainly a key component in achieving greater productivity, it’s not the entire answer. It’s equally important to optimize all aspects of a manufacturing operation from raw materials through delivery to the customer. Two Okuma CNC machines used to make pipe couplings are tended by a FANUC R2000 iB robot in this

Two Okuma CNC machines used to make pipe couplings are tended by a FANUC R2000 iB robot in this

A dozen APPs are ready to download from cutting tool maker

A dozen APPs are ready to download from cutting tool maker  Just like the online sites you visit to download the latest APPs for your smart phones, tablets and computers, you can now access productivity-enhancing APPs for your Okuma CNC machines from the

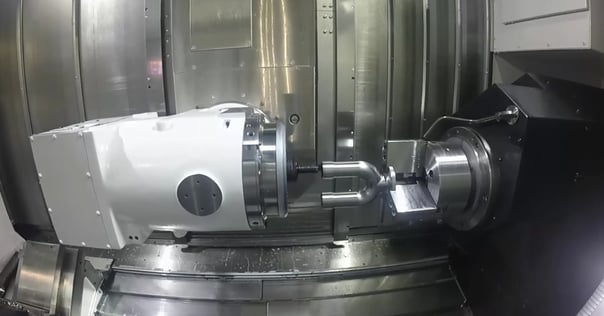

Just like the online sites you visit to download the latest APPs for your smart phones, tablets and computers, you can now access productivity-enhancing APPs for your Okuma CNC machines from the .jpg) A new series of high-accuracy multitasking CNC lathes dramatically reduces the number of fixtures required for complex part machining, thus reducing setup time while increasing machine uptime. Now available from Okuma and Gosiger, the

A new series of high-accuracy multitasking CNC lathes dramatically reduces the number of fixtures required for complex part machining, thus reducing setup time while increasing machine uptime. Now available from Okuma and Gosiger, the  Milling this complex part from pre-hardened 4140 steel (36 Rc) required a combination of a machine tool capable of both high speeds and the ability to precisely control machine movements, an assortment of high-performance cutting tools, and the right CAM software. In this

Milling this complex part from pre-hardened 4140 steel (36 Rc) required a combination of a machine tool capable of both high speeds and the ability to precisely control machine movements, an assortment of high-performance cutting tools, and the right CAM software. In this  Chatter, the vibration created when CNC machine tooling engages a work piece, affects turning, milling, and drilling operations, but is especially troublesome for milling. Even minimal chatter can shorten tool life and impact part quality. Too much chatter can even damage machine tools.

Chatter, the vibration created when CNC machine tooling engages a work piece, affects turning, milling, and drilling operations, but is especially troublesome for milling. Even minimal chatter can shorten tool life and impact part quality. Too much chatter can even damage machine tools..jpg)

Aerospace machining represents a great opportunity for CNC machine shops that are searching for new income streams. However there are a number of challenges to overcome and specialized skills required.

Aerospace machining represents a great opportunity for CNC machine shops that are searching for new income streams. However there are a number of challenges to overcome and specialized skills required. Workplace safety is a major concern for the makers of manufacturing equipment and for machine tool distributors and automation specialists like Gosiger. Modern machine tools are equipped with various safety components that prevent users from accessing critical areas while the machine is operating. Likewise, automation systems using robots and other loading/unloading devices employ safety cages with access doors that are locked during machining cycles, light curtains that stop robot or machine activity when the beam is interrupted, and other safety precautions.

Workplace safety is a major concern for the makers of manufacturing equipment and for machine tool distributors and automation specialists like Gosiger. Modern machine tools are equipped with various safety components that prevent users from accessing critical areas while the machine is operating. Likewise, automation systems using robots and other loading/unloading devices employ safety cages with access doors that are locked during machining cycles, light curtains that stop robot or machine activity when the beam is interrupted, and other safety precautions..jpg) It’s no secret that factory automation is one of the keys to improving manufacturing productivity. Of course, the term “automation” includes a number of technologies that can be applied to various manufacturing functions. The trick is to integrate the right components into a seamless automated system that best meets your needs.

It’s no secret that factory automation is one of the keys to improving manufacturing productivity. Of course, the term “automation” includes a number of technologies that can be applied to various manufacturing functions. The trick is to integrate the right components into a seamless automated system that best meets your needs. Most of us have become addicted to various APPS on our personal computers and mobile devices. They make life easier and richer by enabling us to perform a wide variety of activities at our desks and on the go. APPS also serve us well on the factory floor and when away from our shops so we can monitor activities and improve productivity.

Most of us have become addicted to various APPS on our personal computers and mobile devices. They make life easier and richer by enabling us to perform a wide variety of activities at our desks and on the go. APPS also serve us well on the factory floor and when away from our shops so we can monitor activities and improve productivity. Because the computers and electronics that enable us to program and control CNC machine tools are typically housed in a protective cabinet, we sometimes forget that they are still subject to damage if heat builds up or debris finds its way into the enclosure. In fact, a widely accepted rule of thumb is that the rate of failure for electronic devices is cut in half for every 50º F (10º C) decrease in temperature.

Because the computers and electronics that enable us to program and control CNC machine tools are typically housed in a protective cabinet, we sometimes forget that they are still subject to damage if heat builds up or debris finds its way into the enclosure. In fact, a widely accepted rule of thumb is that the rate of failure for electronic devices is cut in half for every 50º F (10º C) decrease in temperature. Finding qualified CNC machine operators and other manufacturing personnel today can be challenging and raises questions about future workforce availability. One solution, of course, is to work with local schools to encourage students to consider a career in manufacturing and point them toward appropriate educational opportunities.

Finding qualified CNC machine operators and other manufacturing personnel today can be challenging and raises questions about future workforce availability. One solution, of course, is to work with local schools to encourage students to consider a career in manufacturing and point them toward appropriate educational opportunities. According to survey data released by

According to survey data released by

THE RIGHT MACHINE FOR THE RIGHT PRICE

THE RIGHT MACHINE FOR THE RIGHT PRICE Machining aluminum alloys for aerospace, electronics, computers, and other applications presents a number of challenges for CNC machine shops. If you’re considering expanding your capabilities to include making aluminum alloy parts, there are a number of important factors to consider:

Machining aluminum alloys for aerospace, electronics, computers, and other applications presents a number of challenges for CNC machine shops. If you’re considering expanding your capabilities to include making aluminum alloy parts, there are a number of important factors to consider:

Many newer cars have maintenance reminders built in that alert owners when it’s time for routine services like oil changes, which is a great convenience. Surprisingly, having this feature doesn’t keep some drivers from putting off servicing the vehicle until problems arise. True, you still must make the appointment and then either wait, or leave and arrange for someone to take you back to pick up the vehicle. However most of us realize that it’s important to protect this major investment, and that preventative maintenance is less costly and less inconvenient than dealing with a breakdown.

Many newer cars have maintenance reminders built in that alert owners when it’s time for routine services like oil changes, which is a great convenience. Surprisingly, having this feature doesn’t keep some drivers from putting off servicing the vehicle until problems arise. True, you still must make the appointment and then either wait, or leave and arrange for someone to take you back to pick up the vehicle. However most of us realize that it’s important to protect this major investment, and that preventative maintenance is less costly and less inconvenient than dealing with a breakdown.

Dayton OH – According to machine tool distributor and factory automation specialist,

Dayton OH – According to machine tool distributor and factory automation specialist,  With 2013 winding down, we’re all looking forward to the promise of another good year for manufacturing in 2014 and, although it may seem far away, we’re also looking forward to IMTS 2014. Early indications are that a record number of exhibitors and visitors will grace the halls of McCormick place next September 8 – 13. Certainly there will be exciting new technologies and sharing of information that will help everyone from the smallest CNC machine shop to the largest mega-manufacturers advance their operations. Here are a few other highlights according to information released by The Association for Manufacturing Technology (AMT).

With 2013 winding down, we’re all looking forward to the promise of another good year for manufacturing in 2014 and, although it may seem far away, we’re also looking forward to IMTS 2014. Early indications are that a record number of exhibitors and visitors will grace the halls of McCormick place next September 8 – 13. Certainly there will be exciting new technologies and sharing of information that will help everyone from the smallest CNC machine shop to the largest mega-manufacturers advance their operations. Here are a few other highlights according to information released by The Association for Manufacturing Technology (AMT). Investing in a 5-axis CNC machine can open doors to greater productivity, reduced capital investment, lower operator-cost-per-part and the opportunity to accept work from customer previously unavailable to you. How is this possible? Because simultaneous 5-axis machining provides all of these benefits:

Investing in a 5-axis CNC machine can open doors to greater productivity, reduced capital investment, lower operator-cost-per-part and the opportunity to accept work from customer previously unavailable to you. How is this possible? Because simultaneous 5-axis machining provides all of these benefits: Lean manufacturing has been around for quite a while, and many manufacturers have embraced the philosophy of continuously looking for ways to eliminate waste in their processes. However, the true meaning of Lean involves much more than automating an activity or streamlining an operation, as important as those things are. So here are 7 questions to ask yourself about your Lean program.

Lean manufacturing has been around for quite a while, and many manufacturers have embraced the philosophy of continuously looking for ways to eliminate waste in their processes. However, the true meaning of Lean involves much more than automating an activity or streamlining an operation, as important as those things are. So here are 7 questions to ask yourself about your Lean program. Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper

Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper  CNC machine tool users typically love new technologies. That’s why most have embraced the digital world through computer networks, remote monitoring and reporting, mobile devices loaded with APPs, and online transmission of CAD drawings and other important data.

CNC machine tool users typically love new technologies. That’s why most have embraced the digital world through computer networks, remote monitoring and reporting, mobile devices loaded with APPs, and online transmission of CAD drawings and other important data.

Long rods and shafts that require multiple operations can be efficiently machined on one Swiss-type lathe – if part of a well thought out work cell. Gosiger High Volume department met this challenge as demonstrated in this brief video of a customer installation.

Long rods and shafts that require multiple operations can be efficiently machined on one Swiss-type lathe – if part of a well thought out work cell. Gosiger High Volume department met this challenge as demonstrated in this brief video of a customer installation. For the third year, Gardner Research conducted an in-depth study of CNC machine shops to better understand the reasons some companies perform better in terms of income, profit and growth. The study focused on 4 keys to success:

For the third year, Gardner Research conducted an in-depth study of CNC machine shops to better understand the reasons some companies perform better in terms of income, profit and growth. The study focused on 4 keys to success: Gosiger encourages all customers to have in place a comprehensive Planned Preventative Maintenance Plan for all of the equipment in their shop. By performing the regular inspections and service that every machine requires, you can avoid unnecessary downtime, lost production, late deliveries and expensive machine repairs.

Gosiger encourages all customers to have in place a comprehensive Planned Preventative Maintenance Plan for all of the equipment in their shop. By performing the regular inspections and service that every machine requires, you can avoid unnecessary downtime, lost production, late deliveries and expensive machine repairs. From December 10 – 12, 2013 Gosiger's partner, Okuma, will present the latest technology tools and strategies to help CNC machine shops maximize productivity and profitability.

From December 10 – 12, 2013 Gosiger's partner, Okuma, will present the latest technology tools and strategies to help CNC machine shops maximize productivity and profitability. Recently a customer asked Gosiger to help reduce the cost of machining complex pump shafts it produces for military and other applications. The CNC machine shop was using 5 machine tools to perform 14 operations on the workpiece, including turning, drilling, milling and hobbing. This required multiple setups, programming, machining cycles, and movement of the part between the 5 machines.

Recently a customer asked Gosiger to help reduce the cost of machining complex pump shafts it produces for military and other applications. The CNC machine shop was using 5 machine tools to perform 14 operations on the workpiece, including turning, drilling, milling and hobbing. This required multiple setups, programming, machining cycles, and movement of the part between the 5 machines. In the world of CNC machining we tend to think of employee training as beginning and ending with “how to” lessons relating to specific machining functions. In fact, companies should be thinking in broader terms and promoting continuous education. Here are 7 suggestions to help you shape an employee education program that works for your business:

In the world of CNC machining we tend to think of employee training as beginning and ending with “how to” lessons relating to specific machining functions. In fact, companies should be thinking in broader terms and promoting continuous education. Here are 7 suggestions to help you shape an employee education program that works for your business: It’s no secret that using robots to handle large, heavy, unwieldy parts reduces production time and eliminates many worker safety issues. However even a basic loading and unloading scenario, like the one in this video, requires much more than simply placing a robot arm in front of a machine tool. Gosiger Automation specializes in thinking through the entire manufacturing process to integrate all of the components necessary to achieve optimum productivity.

It’s no secret that using robots to handle large, heavy, unwieldy parts reduces production time and eliminates many worker safety issues. However even a basic loading and unloading scenario, like the one in this video, requires much more than simply placing a robot arm in front of a machine tool. Gosiger Automation specializes in thinking through the entire manufacturing process to integrate all of the components necessary to achieve optimum productivity. It’s challenging enough to run a successful CNC machine shop these days without worrying about people trying to steal from you. Unfortunately, it’s a reality we all must face. Certainly, there have always been thieves and con artists, however today’s technologies and the rapid pace of business provide new opportunities for them to get hold of your hard earned dollars. Following are 5 of the most common scams aimed at businesses of all sizes and what you can do to keep the scammers’ fingers out of your pocket.

It’s challenging enough to run a successful CNC machine shop these days without worrying about people trying to steal from you. Unfortunately, it’s a reality we all must face. Certainly, there have always been thieves and con artists, however today’s technologies and the rapid pace of business provide new opportunities for them to get hold of your hard earned dollars. Following are 5 of the most common scams aimed at businesses of all sizes and what you can do to keep the scammers’ fingers out of your pocket. Dayton OH – Okuma machine tool distributor and automation systems developer Gosiger, Inc. recommends a new, free APP from Okuma that alerts machine users when routine maintenance is required. If properly used, the Scheduled Maintenance APP helps keep machines operating at peak efficiency and reduces downtime and workflow interruptions.

Dayton OH – Okuma machine tool distributor and automation systems developer Gosiger, Inc. recommends a new, free APP from Okuma that alerts machine users when routine maintenance is required. If properly used, the Scheduled Maintenance APP helps keep machines operating at peak efficiency and reduces downtime and workflow interruptions. Owners and managers of CNC machine shops are typically hands on people. They often get started by running jobs themselves, and some never stop. As the business grows, however, many get bogged down in administrative duties, meeting with customers (extremely important), and putting out fires. All of which may keep them from spending time on the production floor.

Owners and managers of CNC machine shops are typically hands on people. They often get started by running jobs themselves, and some never stop. As the business grows, however, many get bogged down in administrative duties, meeting with customers (extremely important), and putting out fires. All of which may keep them from spending time on the production floor. All machine tools and peripheral equipment come with instruction manuals and parts books. These days they may be electronic files in place of or in addition to paper books. The electronic versions are particularly handy as they are easier to store and find. Plus you can usually use them on your PC, laptop, tablet, or other mobile device.

All machine tools and peripheral equipment come with instruction manuals and parts books. These days they may be electronic files in place of or in addition to paper books. The electronic versions are particularly handy as they are easier to store and find. Plus you can usually use them on your PC, laptop, tablet, or other mobile device. Despite improvements in the overall economy, unemployment in the U.S. remains higher than desirable. Even so there are CNC machine shops that can’t find qualified candidates for available jobs. One reason is that experienced machine operators who are capable of working with today’s advanced manufacturing equipment are hard to find. Another is that many young people have a misconception of what working in a modern manufacturing facility is like. Worse yet, those who have an interest may not have the opportunity to gain experience with today’s sophisticated CNC machine tools and, therefore, are less desirable new hires.

Despite improvements in the overall economy, unemployment in the U.S. remains higher than desirable. Even so there are CNC machine shops that can’t find qualified candidates for available jobs. One reason is that experienced machine operators who are capable of working with today’s advanced manufacturing equipment are hard to find. Another is that many young people have a misconception of what working in a modern manufacturing facility is like. Worse yet, those who have an interest may not have the opportunity to gain experience with today’s sophisticated CNC machine tools and, therefore, are less desirable new hires. According to a recent survey by Monster.com, nearly half of the employees who responded say they are unhappy in their current jobs and 81% plan to look for a new job this year. That’s a frightening statistic for employers who are likely unaware that they have disgruntled employees.

According to a recent survey by Monster.com, nearly half of the employees who responded say they are unhappy in their current jobs and 81% plan to look for a new job this year. That’s a frightening statistic for employers who are likely unaware that they have disgruntled employees. Dating back to the time when all machine tools were operated manually and part tolerances were more forgiving, the “C” machine design was the industry standard. When CNC came along, dimensional tolerances tightened and manufacturers demanded faster spindle speeds to deal with harder-to-machine alloys, the inherent performance problems with the “C” design became obvious. We asked Jim Endsley, Product Specialist Machining Centers for Okuma, to explain why the company moved from “C” designs to the current double column or bridge design. Here are the facts Jim shared with us:

Dating back to the time when all machine tools were operated manually and part tolerances were more forgiving, the “C” machine design was the industry standard. When CNC came along, dimensional tolerances tightened and manufacturers demanded faster spindle speeds to deal with harder-to-machine alloys, the inherent performance problems with the “C” design became obvious. We asked Jim Endsley, Product Specialist Machining Centers for Okuma, to explain why the company moved from “C” designs to the current double column or bridge design. Here are the facts Jim shared with us: Dayton, OH – Machine Tool Distributor and Automation Systems Integrator Gosiger, Inc. has developed a new product to enable Okuma CNC machine users to seamlessly integrate a variety of peripheral devices such as bar feeders, high-pressure coolant systems, hydraulically activated fixtures and steady rests through one interface to the machine’s OSP 200 and above control.

Dayton, OH – Machine Tool Distributor and Automation Systems Integrator Gosiger, Inc. has developed a new product to enable Okuma CNC machine users to seamlessly integrate a variety of peripheral devices such as bar feeders, high-pressure coolant systems, hydraulically activated fixtures and steady rests through one interface to the machine’s OSP 200 and above control. Gosiger Controls Specialist Jon Weaver shot this video of a Remote Offset application developed for a Gosiger machining cell customer. Using the Okuma Application Program Interface (API) that enables programmers to create Windows®-based APPs for the Okuma OSP operating system, this program provides the cell operators an easy way to adjust tool offsets from outside the cell.

Gosiger Controls Specialist Jon Weaver shot this video of a Remote Offset application developed for a Gosiger machining cell customer. Using the Okuma Application Program Interface (API) that enables programmers to create Windows®-based APPs for the Okuma OSP operating system, this program provides the cell operators an easy way to adjust tool offsets from outside the cell. For most manufacturers investing in any CNC machine tool is a major decision, and well it should be. Operating costs continue to rise while competition and customer demands can drive profit margins down. So investing in new equipment is a serious proposition. Yet sometimes, in an effort to keep the initial investment to a minimum, some shops fail to see the bigger picture. Take

For most manufacturers investing in any CNC machine tool is a major decision, and well it should be. Operating costs continue to rise while competition and customer demands can drive profit margins down. So investing in new equipment is a serious proposition. Yet sometimes, in an effort to keep the initial investment to a minimum, some shops fail to see the bigger picture. Take

Most of us first heard the term “horsepower” when we became interested in motor vehicles. As youngsters, the concept was pretty simple: More horsepower meant faster cars. That was before we learned about the other factors that affect automobile performance such as torque and RPM.

Most of us first heard the term “horsepower” when we became interested in motor vehicles. As youngsters, the concept was pretty simple: More horsepower meant faster cars. That was before we learned about the other factors that affect automobile performance such as torque and RPM. Managers and owners of CNC machine shops are always striving for greater productivity through new techniques and technologies. It’s true that more capable machine tools and automating certain functions are keys to improving performance. However, even the most advanced manufacturing facilities need talented, committed people to make the most of these tools. So how do you keep your employees motivated?

Managers and owners of CNC machine shops are always striving for greater productivity through new techniques and technologies. It’s true that more capable machine tools and automating certain functions are keys to improving performance. However, even the most advanced manufacturing facilities need talented, committed people to make the most of these tools. So how do you keep your employees motivated? This video shows how a Fanuc M-20iA six-axis industrial robot equipped with an IRVision system locates, picks up and loads parts into an

This video shows how a Fanuc M-20iA six-axis industrial robot equipped with an IRVision system locates, picks up and loads parts into an  Change is often difficult. We tend to get comfortable in the way we’ve always done things. Then there’s the fear of making a bad decision, which can cloud our judgment. That’s why it’s important to carefully consider the advantages and disadvantages when expanding or upgrading your CNC machine capabilities.

Change is often difficult. We tend to get comfortable in the way we’ve always done things. Then there’s the fear of making a bad decision, which can cloud our judgment. That’s why it’s important to carefully consider the advantages and disadvantages when expanding or upgrading your CNC machine capabilities. CNC machine cutting tools are perishable by nature, but that doesn’t mean you can’t take steps to prolong the life of your cutting tools. Not only are the tools, themselves, an expense but replacing worn tools can interrupt production and add labor costs. Not replacing worn tools in a timely manner can also impact the quality of a workpiece.

CNC machine cutting tools are perishable by nature, but that doesn’t mean you can’t take steps to prolong the life of your cutting tools. Not only are the tools, themselves, an expense but replacing worn tools can interrupt production and add labor costs. Not replacing worn tools in a timely manner can also impact the quality of a workpiece. As the U.S. economy continues to improve, CNC manufacturers are attempting to add to their workforce. Some of the individuals showing up for these jobs are foreign-born. As we are all aware from the ongoing debates in Washington over immigration reform, there are many unauthorized workers in this country.

As the U.S. economy continues to improve, CNC manufacturers are attempting to add to their workforce. Some of the individuals showing up for these jobs are foreign-born. As we are all aware from the ongoing debates in Washington over immigration reform, there are many unauthorized workers in this country. Dayton, OH – Earlier this year Gosiger, Inc. OEM partner,

Dayton, OH – Earlier this year Gosiger, Inc. OEM partner,