Okuma’s Turn-Cut Function Eliminates Special Tooling and Secondary Machines

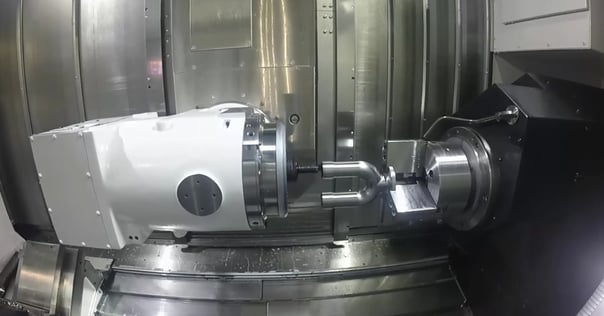

Okuma Multus series multi-function, 5-axis CNC turning centers enable one-and-done machining of even complex parts. The exclusive Turn-Cut feature is just one of the many ways Multus machines eliminate the need to move a part to a dedicated lathe for specialized operations such as machining surfaces along the z-axis that have varying diameter shapes or, as demonstrated in this video, making ID and OD cuts.

Turn-Cut technology synchronizes the X and Y circular motion with the spindle angle so the tool edge maintains its path throughout the application. Because there is no need to move the part to another machine, you also eliminate additional fixturing and significantly reduce setup times.

To learn more about how Okuma 5-axis machines can ramp up production, enable you to take on more complex and challenging work, and make your shop more competitive, contact your local Gosiger facility.