Additionally, the exclusive THINC-OSP control enables quick and easy setup and operation. This combination of stability, speed and accuracy makes these machines ideal for machining aerospace, automotive and other large-format workpieces, as proven by the over 8,000 Okuma Double Column Machining Centers sold world-wide.

Using double column construction based on fine element method (FEM) analysis, these VMCs combine rigidity, dimensional stability and blazing fast throughput to reduce your costs while turning out high-quality, precise parts.

Among the fastest VMCs in the industry, the MB-V Series has zero table overhang, an ergonomic front access design and uses minimal floor space. Ideal for high-speed machining of die molds and other close tolerance parts, MB-V machines are equipped with a high speed, high power 40 Taper 8,000 rpm spindle and quick-acting, 20-position automatic tool changer. Thermo-Friendly Design is standard.

Options include Collision Avoidance System and Machining Navi.

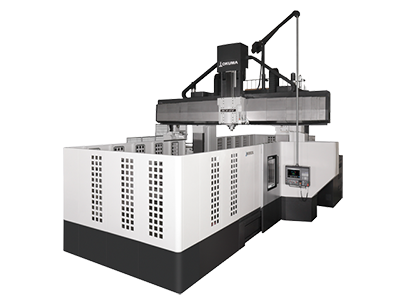

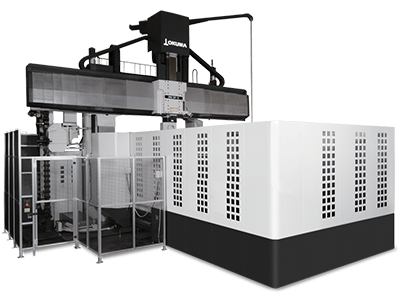

The MCR Series offers a full-line of double-column machining centers for 5-sided applications. Designed with auto attachment changers (AAC), this series provides a wide selection of work envelopes and spindle motor outputs. Large parts that require high accuracies demand to be cut on the MCR Series.

A double-column machining center for 5-face applications that offers high accuracy precision for the large-part machining market.

High-speed, high-quality double column machining center with outstanding dimensional accuracy and surface quality.

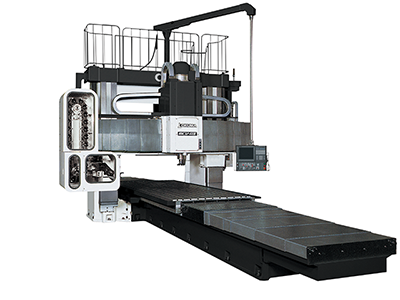

A space-saving, high-speed, vertical double-column machining center with a fixed crossrail provides top surface machining for medium-sized and large dies/molds and parts.

Not every job requires all the bells and whistles. But every job does deserve the best. The MCV-AII is designed to provide top quality double-column machining at an affordable price. With an easily-operated vertical quill and available simple 5-Face Machining, the MCV-AII is the perfect solution for powerful cutting on medium and large size parts. And thanks to our hybrid guides, the load limit increases tremendously without compromising stability. The result is a simple yet robust machine that is built to last.

Flexible and durable double column machining center for medium- to large-size parts.

With the same double-column structure that has been so widely praised in Okuma's double-column machining centers, the VTR-A series machines provide both high rigidity and high accuracy in a large work envelope. This series is designed to handle heavy-duty cutting, including difficult-to-machine and thin or tall cylindrical materials and can easily cut or mill workpieces of various sizes.

With optional Thermo-Friendly Concept features, added thermal stability can bring even greater accuracy and repeatability for even the most demanding of tolerances.