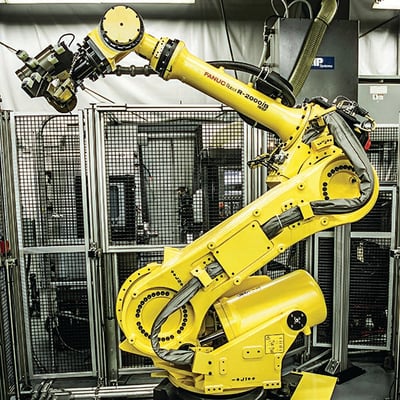

Specializing in delivering robotic machine tending solutions that streamline operations. Find the right solution with our complete automation ecosystem, whether you're looking to automate the loading/unloading of a single CNC machine or enhance the workflow of an entire production line. With over 1,000 successful installations across US factories and 90+ years of working in the machine tool industry, we have the knowledge and expertise to design and manufacture automation solutions tailored to your requirements.

Specializing in delivering robotic machine tending solutions that streamline operations. Find the right solution with our complete automation ecosystem, whether you're looking to automate the loading/unloading of a single CNC machine or enhance the workflow of an entire production line. With over 1,000 successful installations across US factories and 90+ years of working in the machine tool industry, we have the knowledge and expertise to design and manufacture automation solutions tailored to your requirements.

Manufacturers continuously face the increasing pressure to provide quality parts faster while managing labor challenges and rising costs. CNC machine tending automation addresses these challenges by delivering measurable results across every process of your operation:

![]()

Create more consistent parts and speed up deliverability, all while cutting operation and labor costs.

![]()

Cut manual labor and increase efficiency, adding more to the bottom line.

![]()

Keep your entire process running without needing to manually load parts or man a controller.

![]()

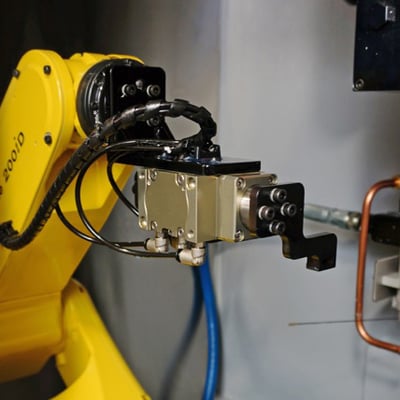

Much like your CNC control, an industrial robot will always do what you program it to do.

![]()

Increase equipment utilization through the use of robotic automation by 200 to 400%.

![]()

CNC machine tending automation produces more parts-per-hour by 47% for manufacturers.

![]()

Increase machine hours annually with automation by 2,000 to 6,000.

![]()

Improve quality and lead times by 30% while reducing costs.

Okuma ORLs provide a simple and effective entry-level automation option for CNC machine tending operations.

ORL-R (Rotary) - Rotating platform and disc-style storage unit for high-speed, high-volume production of identical parts, allowing an operator to load/unload while the robot loads/unloads the machine

ORL-D (Drawer) - Features a drawer to hold and store components that the operator and robot can simultaneously load/unload parts for dual process operations

ORL-MC (Machining Center) - For mixed parts, low-volume automation, featuring a three-sided rotation station for parallel loading/unloading of workpieces for multiple operations

Automation Within Reach expands its offering into a complete automation ecosystem—from standard to

fully tailored CNC machine tending solutions. By combining our standard and custom automation solutions (formerly Gosiger Automation), AWR provides simplistic and complex machine tending options for manufacturers across all stages of their automation journey.

Discover how other manufacturers have improved their CNC workflow with Automation Within Reach.

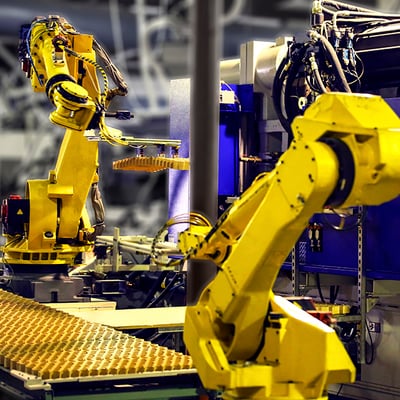

The AWR Flex Series offers standard automation solutions designed to boost productivity and reduce costs. Designed specifically for CNC lathe and mill operations, our DC, RC, and RCX machine tending systems address the challenges of manual processes by offering seamless integration.

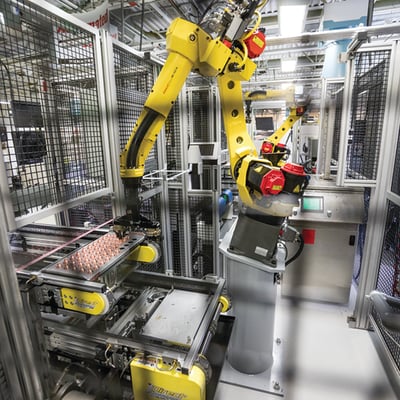

The Plus Series boosts efficiency and minimizes downtime with AWR's pre-engineered CNC machine tending solutions designed for quick implementation and maximum productivity. Offering three-cell options—Drawer, Conveyor, and Pallet—with flexible configurations for single or dual-machine operation and custom end-of-arm tooling to fit your unique needs.

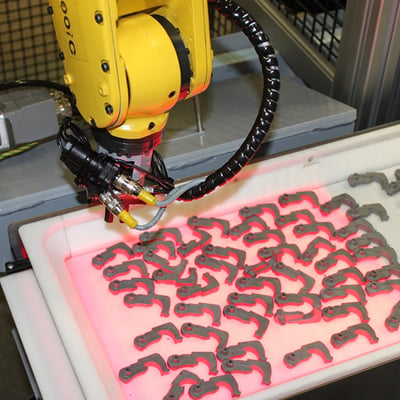

For unique production challenges, AWR's Custom Solutions offer fully tailored automation to fit your specific manufacturing needs. Custom automation integration removes more tedious labor, increases machinery and automation utilization, reduces scrap, and lowers the per-part price of the manufactured component.