Gosiger’s Engineered Systems (Gosiger ESD) is a centralized process-oriented engineering team that continues a 90+ year legacy of enabling machine tool users to maximize their productivity and profitability by providing industry-leading Engineering Services to our customers. We provide fully-integrated solutions from complete Turnkey systems to Engineering support and everything in between. We are here to provide focused solutions for your most complex manufacturing challenges and needs.

ESD can provide contract engineering services that include:

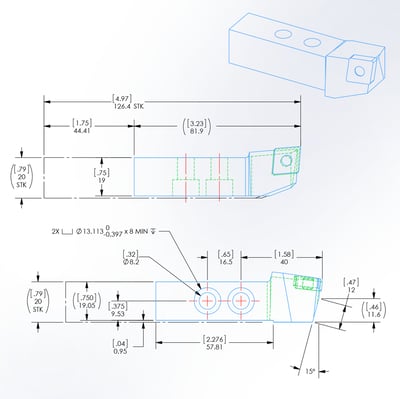

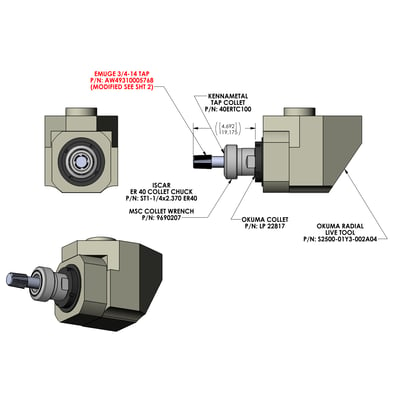

As your single-source partner, ESD will provide all required capital accessories, engineering labor, workholding, tooling, etc., resulting in a guaranteed outcome of cycle time, part quality, and completion date all at a fixed price. Our full turnkey solution will include everything you need to be self-sufficient in operating your system, including onsite training, system validation and qualification as well as detailed engineering documentation for the entire system.

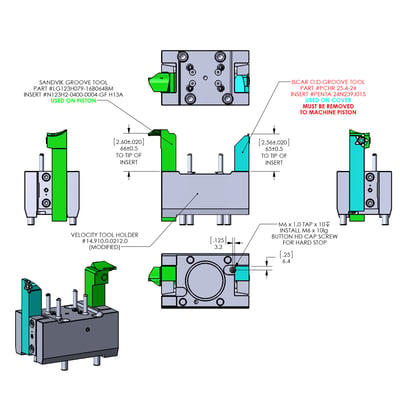

With ESD’s manufacturing industry knowledge and processing expertise, we can work together to develop a complete manufacturing process. Maybe you have workholding and a process for a given part and want to migrate this to a new machine platform-we can help. We can work closely with your manufacturing team to utilize existing hardware and implement the latest machining practices on a new or used machine. ESD will guarantee the outcome of cycle time, part quality, and completion date all at a fixed price.

ESD has full-time CAD/CAM programmers on staff with proficiencies on multiple software platforms and know how to apply today’s latest technologies to position our customers for success. We have experts in the 5-Axis machining arena and experience with utilizing the machines we sell to the fullest.

From training on your first 5-Axis machine, complex 3D geometries, hard milling, or working with your programmers on the latest industry best practices - we are here to help.

Are you wanting to understand how to apply Additive Manufacturing to the shop floor? We can help! With our Stratasys and Desktop Metals product line we are uniquely positioned to offer advice on how to make Additive work for you. From shop organization, part holding fixtures, simple gauges to prototype parts we are at the forefront of how to apply this technologies to manufactures.

Our Engineered Systems Division could only be as successful as it is with the support of our industry partners. Our relationships with these industry leaders allow us to provide you with the best quality products possible. Browse their websites below to learn more about what they offer.

ESD is driven to transform customer relationships and become viewed as an engineering partner helping our customers solve manufacturing challenges. We are focused on providing industry leading engineering solutions as well as creating value for our customers. Our ESD team has been involved in solving hundreds of customers' challenges all across the country.

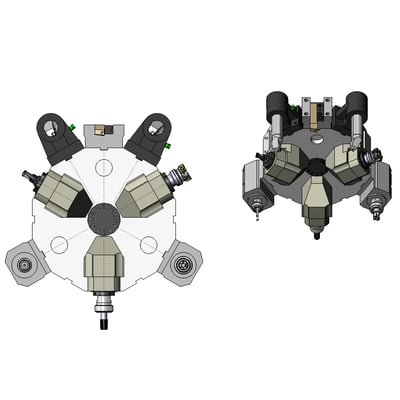

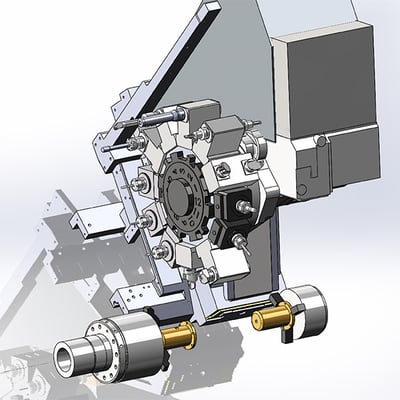

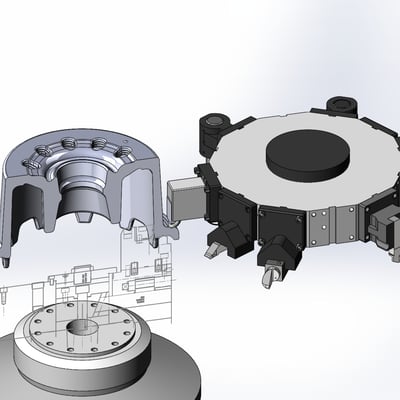

The Gosiger ESD Auto Unloader is a low-cost, highly-effective solution for automating the unloading process of machine tools fed with a barfeeder. With a small footprint and the ability to be safely integrated with your machine tool, the Auto Unloader can greatly improve your machine's uptime.