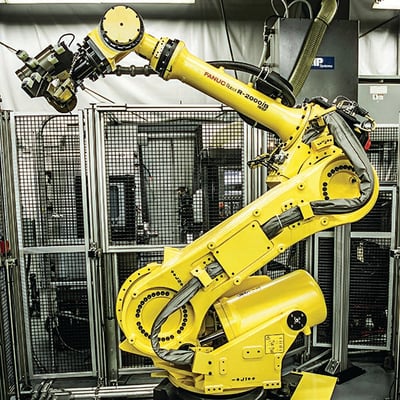

Gosiger Automation specializes in applying robotics to streamline workpiece flow. The result is improved throughput, reduced direct labor costs, consistent part quality and faster deliveries. Whether you’d like to automate the loading and unloading of a single machine tool or enhance the workflow of an entire production line, we can help. With over 1000 successful installations in factories throughout the U.S. and 90+ years of working in the machine tool industry, Gosiger Automation has the talent and experience to develop a solution that precisely meets your needs.

![]()

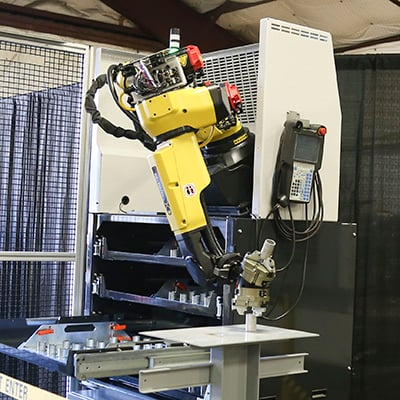

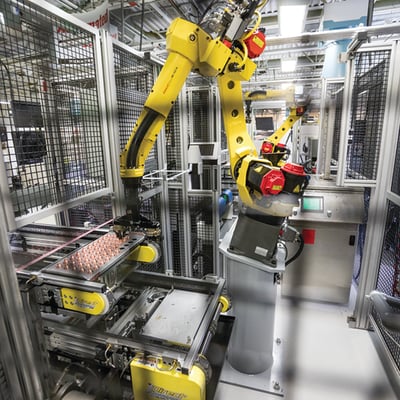

Create more consistent parts and speed up deliverability, all while cutting operation and labor costs.

![]()

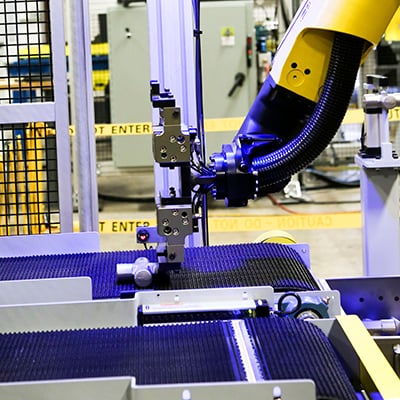

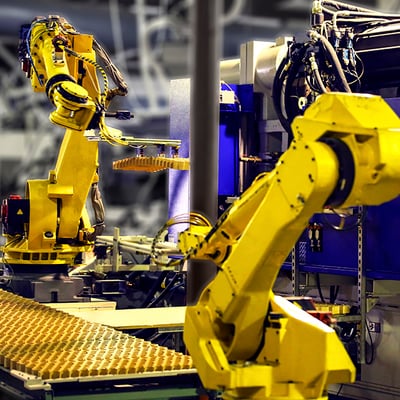

Cut manual labor and increase efficiency, adding more to the bottom line.

![]()

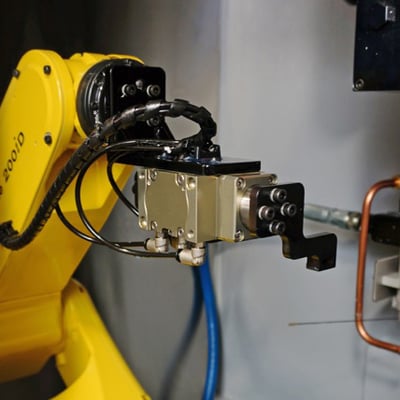

Keep your entire process running without needing to manually load parts or man a controller.

![]()

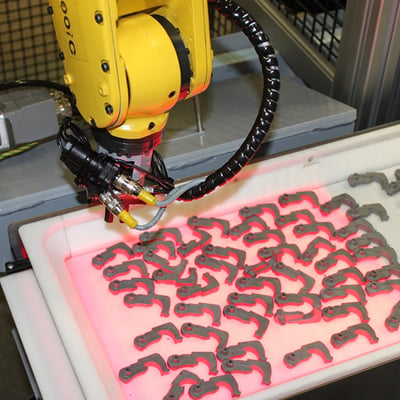

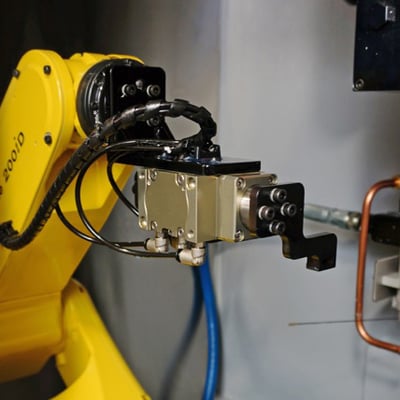

Much like your CNC control, an industrial robot will always do what you program it to do.

At Gosiger Automation, our strength lies in eliminating all customer part touches in a component manufacturing process. We design, build and test your system to ensure your project meets your expectations.

With Custom Automation, automating more processes is usually better than less. By having the automation system do as many things as possible, we remove more tedious labor, increase robot and machine utilization, reduce scrap and lower the per part price of the component being manufactured.

We can design fixtures to organize your parts for easy automated pick-up.

Our 2D vision expertise lets the operator place parts on a conveyor. The operator doesn’t need to worry about part orientation. The robot selects the part and orients it for machine loading.

Our 3D vision bin picking experience often eliminates the need for any kind of special packaging or staging. We can pick the raw material right from a crate eliminating all manual material handling.

We have a great deal of experience with in-process inspection. We use inspection results to automate machining process adjustments, eliminating human error and scrapped parts.

We load raw material and unload finished parts from the machining process. We then move the part to the next operation, more machining, inspection assembly, packaging etc.

Whether installing bearings or assembling bolted joints. We have the capability to eliminate manual labor and errors in the assembly process.

We have experience loading parts to cleaning systems, ovens, rust inhibitor stations.

We have the ability to unload finished parts from your system any number of ways from racks to standard or custom pallets to boxes.

Standard automation from Automation Within Reach is ideally suited to machine tending in a high-mix, low-volume environment, the job shop. AWR machine tending solutions are simple, versatile, and affordable systems for those customers who demand a broad range of parts produced in small lots sizes at increasingly competitive price points with no robotic programming! The interactive user interface allows step-by-step part setup in minutes!

See what others have said about how Automation Within Reach a has improved their workflow.

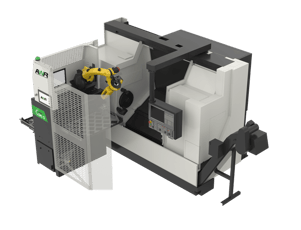

The AWR DC series machine tending system holds various part sizes in a compact footprint, reducing labor and eliminating errors associated with manually loading parts.

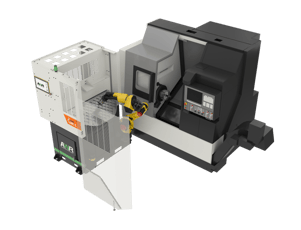

The AWR RC series tending system makes automated machine tending simple and practical for the job shop. Its flexible design lends itself to a very wide variety of part sizes, and its simple operation makes it practical even in low volume high mix environments.

The AWR VBX series delivers easy-to-use, accurate, repeatable, and reliable automation for all shops, including high-mix, low-volume manufacturing.

The AWR RCX series delivers easy-to-use, accurate, repeatable, and reliable automation for all shops, featuring a rotary shelf system.