iFP high-performance vacuum parts washers provide a self-contained, highly efficient and environmentally friendly solution to meet your most demanding parts washing requirements. These systems can safely use the industry’s leading solvents, guaranteeing the best cleaning results for parts manufactured in oil or water base cutting fluids, especially those presenting the most challenging internal or external features. Superior solvent distillation, filtration and oil separation designs combine to assure the most minuscule solvent consumption, reduced labor and highly-reduced waste disposal / handling costs.

iFP is pleased to introduce the KP series of precision part washing platforms serving a wide variety of industrial applications including automotive, fluid power, aerospace, medical and much more.

Whether it’s one of our many standard models ranging from the KP30 to the KP.Max or a custom-built system, iFP and Gosiger lead the field in vacuum chamber washing technology and support.

iFP’s smallest, single basket cleaning platform. Ideal for facilities manufacturing small precision parts with challenging, hard to clean geometries typical of parts found within the medical, dental and Swiss parts industries.

The KP.30 is particularly suitable for the dental, medical and jewelry sectors and a great fit for turned components, fashion accessories, polished parts, fittings, automotive and sintered components.

Our HYBRID systems, thanks to the combined use of modified alcohols and aqueous detergent solutions, obtain the best cleaning results both on organic (oil, grease) and on inorganic (emulsion, salt) contaminants.

Load Size:

11.8" x 17.7" x 7.8"

Max Load Weight:

110 lbs

Dimensions:

98.4" x 78.7" x 118.1"

Cycles Per Hour:

4-8

Load Size:

17.7" x 23.6" x 7.8"

Max Load Weight:

220 lbs

Dimensions:

118.1" x 84.6" x 118.1"

Cycles Per Hour:

4-8

Load Size:

17.7" x 35.4" x 7.8"

Max Load Weight:

330 lbs

Dimensions:

169.3" x 90.6" x 129.9"

Cycles Per Hour:

4-8

Load Size:

17.7" x 47.2" x 7.8"

Max Load Weight:

440 lbs

Dimensions:

169.3" x 90.6" x 129.9"

Cycles Per Hour:

4-8

The ideal product for the most demanding applications. It satisfies high productivity demands and large quantities of contaminants.

It is suitable for die-casting, automotive, precision small parts, taps, oleodynamic components, sintered components, heat exchangers and bent parts.

Load Size:

11.8" x 17.7" x 7.8"

Max Load Weight:

110 lbs

Dimensions:

80.7" x 78.7" x 118.1"

Cycles Per Hour:

4-8

Load Size:

23.6" x 17.7" x 7.8"

Max Load Weight:

220 lbs

Dimensions:

114.2" x 74.8" x 118.1"

Cycles Per Hour:

4-8

Load Size:

35.4" x 17.7" x 7.8"

Max Load Weight:

330 lbs

Dimensions:

128.0" x 90.6" x 126.0"

Cycles Per Hour:

4-8

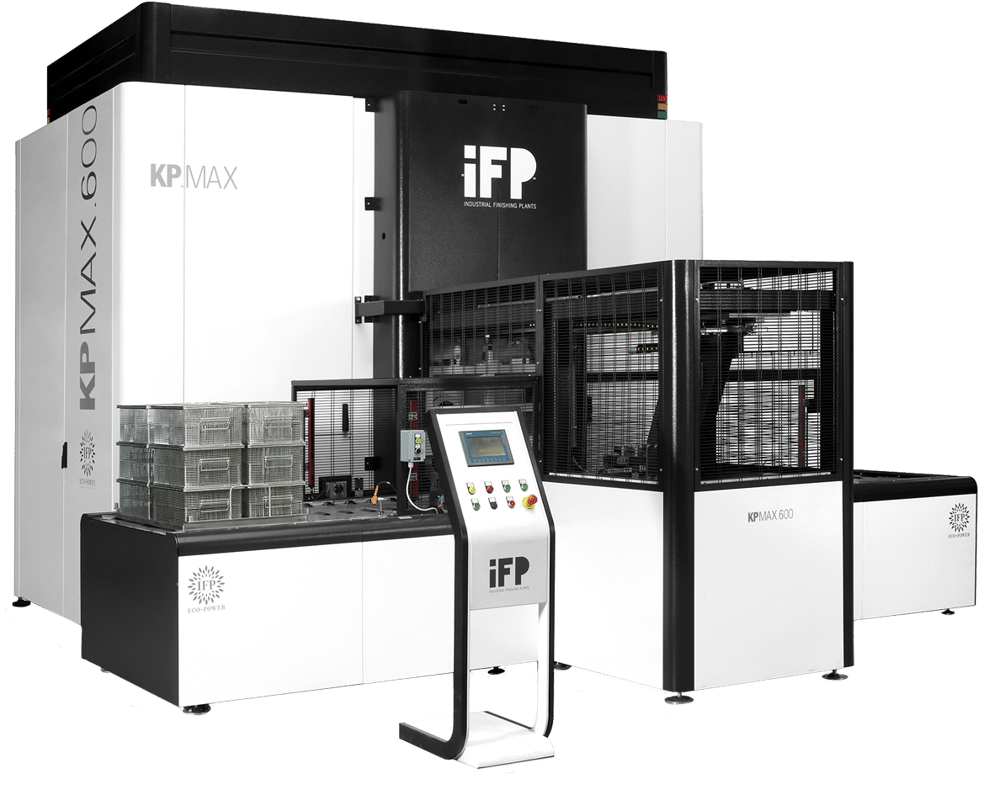

Need more capacity than our standard models? IFP offers serious solutions for many special application requests. It allows for the treatment of very high production volumes or single loads of large dimensions.

The KP.MAX is ideal for material subjected to heat treatment, large elements, oleodynamic components, taps, fittings, automotive parts, sintered components, cutlery, cookware, gears and small, mechanical parts.

Load Size:

47.2" x 17.7" x 15.7"

Max Load Weight:

881 lbs

Dimensions:

149.6" x 106.3" x 135.8"

Cycles Per Hour:

3-4

Load Size:

39.3" x 23.6" x 23.6"

Max Load Weight:

1,322 lbs

Dimensions:

159.4" x 106.3" x 145.7"

Cycles Per Hour:

3-4