Making quality products is your first job. Therefore, our first job is helping you select and configure the very best machines – to work for you today and for years to come.

At Gosiger, we deliver machine tool solutions – including high performance machines, engineering, service, support and parts for every customer – from small shops to fully automated factories. Gosiger offers only the highest quality machines and accessories from the world’s most respected brands, including Okuma, Modig and more. In fact, we’ve been a trusted Okuma partner for over 30 years. Take a look at our capabilities, download some valuable management tools and call us. We’ll put our experts to work for you.

Today’s metalworking shops rely on CNC horizontal lathes to produce items from simple rings and shafts to complex automotive or aerospace parts.

No matter what materials or workpiece sizes you machine, the Gosiger machining specialists will help you find the fixed or sliding headstock horizontal lathe that precisely suits your requirements from these industry leaders:

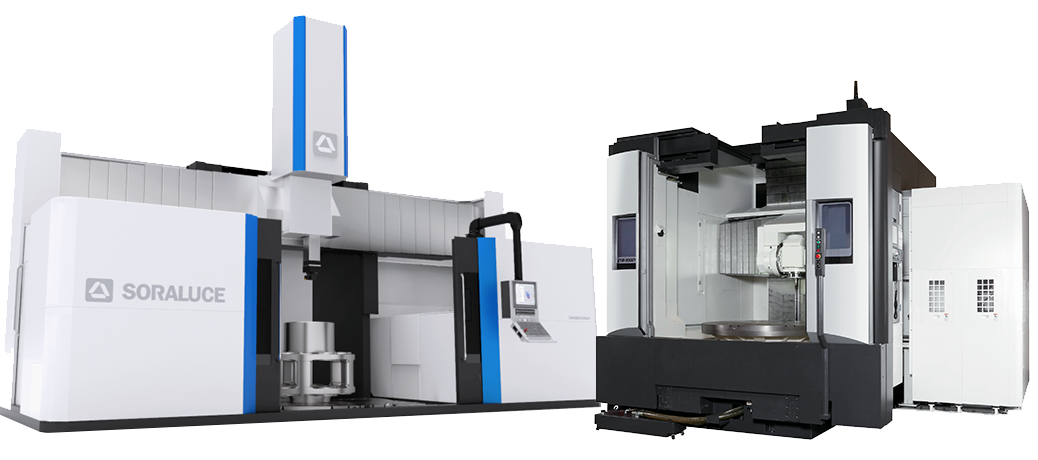

For many applications, including workpieces that are too heavy, bulky or oddly shaped to be efficiently turned on a horizontal lathe, the vertical lathe is the choice of many CNC machine shops.

Okuma leads the industry with 11 distinct models of vertical lathes, including 1, 2, 3, 4 and 5-axis CNC machines. SORALUCE vertical machines create new standards of turning and machining capability for users in the most demanding industries. Momentum offers heavy-duty, ram-type vertical lathes for large and heavy parts.

Let the Gosiger team help you find the right vertical lathe for your unique requirements.

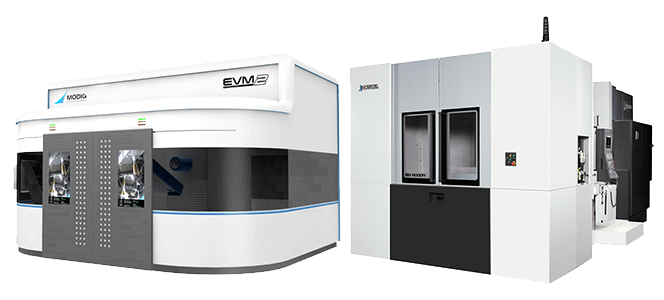

Ideal for machining multi-sided parts and those with complex geometry, Horizontal Machining Centers reduce labor cost-per-part by decreasing setup time and operator touches, eliminating the need to move parts from one machine to another, and reducing the number of fixtures required. HMCs also increase spindle availability so you can take on more work. Learn more about the advantages of HMCs by discussing your needs with a Gosiger machine tool specialist and exploring the wide range of HMCs from Okuma, Modig and FPT.

A mainstay in many CNC shops, Vertical Machining Centers range from accurate and reliable basic models for simple jobs to more advanced versions including 5-axis VMCs for complex, multi-sided parts.

Okuma, Jingdiao and Modig each offer a wide variety of VMC types and sizes to accommodate your specific applications. Contact Gosiger to learn more.

If you perform a number of operations on multi-sided workpieces, a 5-Axis Machining Center will significantly improve your productivity.

Here’s how: With 5-Axis capability you can entirely machine a part in a single cycle, all in one place. This means there are fewer operator touches, which reduces labor costs and human error. You also eliminate the need for additional fixtures and replace several machine tools with one unit. Contact Gosiger for all the facts on 5-axis machines built by Okuma, Modig and Jingdiao.

NomuraDT doesn't sacrifice time for quality. The rigid structural design of their machines - coupled with a BBT30 taper spindle with double face contact - decreases vibration in the cutting process, improving part quality and guaranteeing longer tool life. The highly productive automatic tool changer and high rapid traverse speeds make their drill/tap centers a solid fit for ultra-fast machining.

For many machined parts the grinding operation is a critical stage that requires a dedicated, highly accurate machine tool.

No matter how simple or complex your I.D. and O.D. requirements, Gosiger advisors will help you choose a grinder that perfectly suits your needs. We have Okuma models for parts as small as 3 mm as well as grinders for large parts weighing up to 660 lbs.

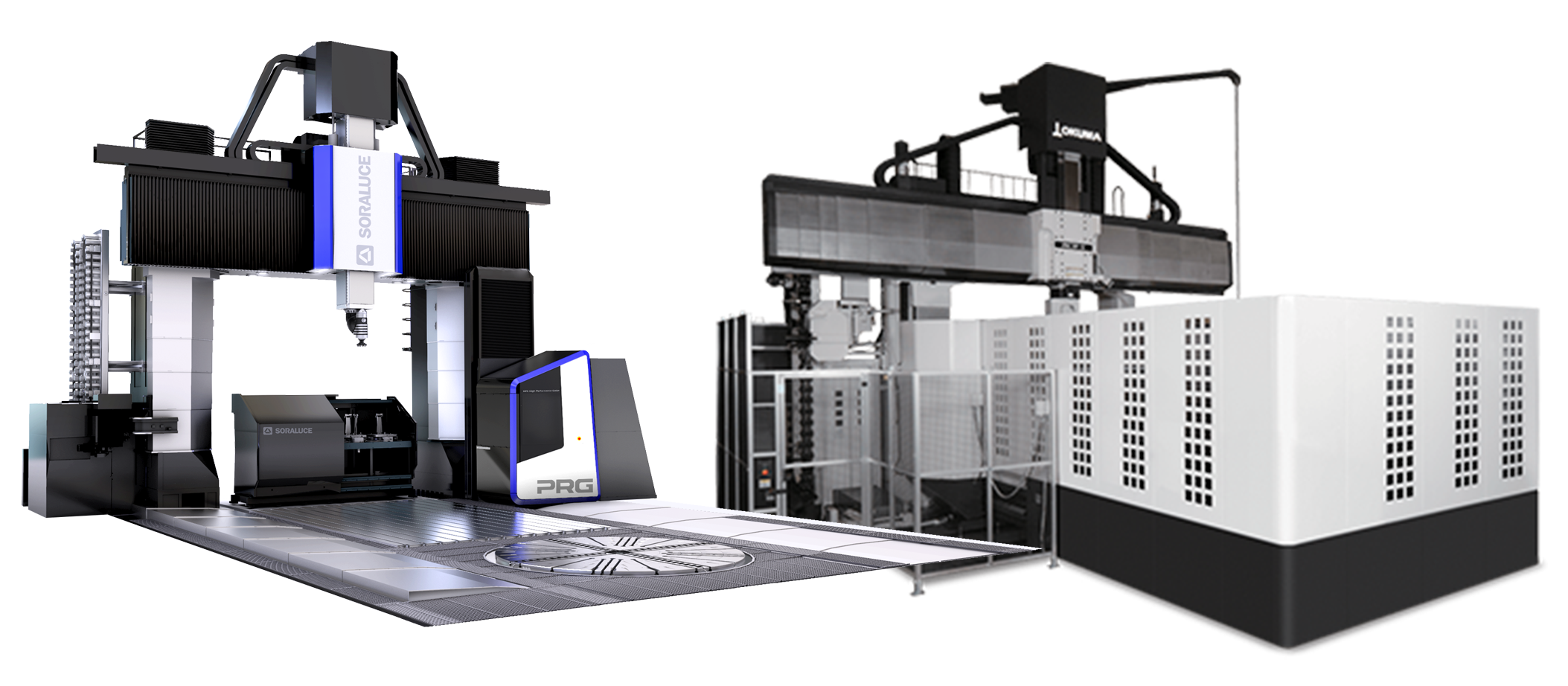

Double column machining centers are dependable and can provide the strength and power for heavy-duty industries including aerospace, electronics and automotive.

They are built on rigid bases to create a strong foundation to support two columns, and a bridge-type structure supports the machine head. Designed to handle medium to large parts, these machines can get any job done quickly and efficiently.

Momentum’s unique MFB flat bed lathe series provides, in addition to its standard tool turret, a second set of Z-axis guideways with its own dedicated sub-carriage and head. This enables the interference-free use of long, deep-hole boring or drilling attachments. The MFB is perfect for cylinders and similar parts needing internal machining.

For more than 50 years, NomuraSwiss has designed and crafted precise, reliable Swiss-style turning machines. The very nature of a sliding headstock machine requires greater attention to detail, and that has always been a distinguishing characteristic of NomuraSwiss machines.

NomuraSwiss Swiss-style turning machines are ideal for machining complex parts, working with difficult-to-machine materials, achieving fine surface finishes and reducing tool costs.

iFP high performance vacuum parts washers provide a self-contained, highly efficient and environmentally friendly solution to meet your most demanding parts washing requirements.

iFP systems can safely use the industry’s leading solvents, guaranteeing the best cleaning results for parts manufactured in oil or water base cutting fluids, especially those presenting the most challenging internal or external features.

Superior solvent distillation, filtration and oil separation designs combine to assure the most miniscule solvent consumption, reduced labor and highly reduced waste disposal / handling costs.

The Modig HHV (horizontal high velocity) bar and extrusion mills are hybrid horizontal machining centers specially designed to efficiently machine parts from extrusions and bar stock. Articulated work supports eliminate the need for complex part fixturing and the need to pre-cut material into blanks. The rotary U axis enables machining of four sides of a part in addition to qualifying both ends of the workpiece.

As technology advances, automation is not only suited for high production environments any longer. Gosiger offers both custom & standard “out of the box” solutions for all types of machines and processes, and they’re more affordable, more flexible and easier to use than ever before. The Load & Go from Automation Within Reach is a simple, versatile, and affordable system for standard machine tending needs, and Gosiger's Automation team is ready to develop a custom solution that precisely meets your needs.

We have partnered with one of the leading providers of 3D printing and additive manufacturing solutions

Gosiger has long advocated for the breakthrough technologies that give our customers the advantages they need to compete in the increasingly competitive global manufacturing marketplace.

Industry 4.0 continues to evolve and materialize, leading to breakthrough levels of efficiency and precision. To keep up, we have partnered with Stratasys. Stratasys provides complete polymer 3D printing solutions for every stage of the product life cycle.